Inspector

Jay Peters

321-877-6247

|

INSPECTION REPORT

6715 Bass Hwy

St Cloud FL 34771

|

INSPECTED BY Jay Peters 20/20 Inspection Solutions |

INSPECTION DATE

3/5/2021 3/5/2021 01:00 PM 01:00 PM |

General Info

|

Property Address

6715 Bass Hwy St Cloud FL 34771 |

Date of Inspection

3/5/2021 |

Report ID

20210305-6715-Bass-Hwy |

|

Customer(s)

John Austin |

Time of Inspection

01:00 PM |

Real Estate Agent

Fernando Homs HOMS REALTY GROUP INC. |

|

In Attendance:

Inspector |

Type of building:

Single Family (1 story) |

Approximate age of building:

Over 25 Years |

|

Temperature:

Over 65 (F) = 18 (C) |

Weather:

Clear |

Ground/Soil surface condition:

Dry |

|

Rain in last 3 days:

Yes |

Radon Test:

No |

Water Test:

No |

Comment Key or Definitions

The following definitions of comment descriptions represent this inspection report. All comments by the inspector should be considered before purchasing this home.

Any recommendations by the inspector to repair or replace suggests a second opinion or further inspection by a qualified contractor. All costs associated with further

inspection fees and repair or replacement of item, component or unit should be considered before you purchase the property.

Inspected (IN) = I visually observed the item, component or unit and if no other comments were made then it appeared to be functioning as intended allowing for

normal wear and tear.

Not Inspected (NI)= I did not inspect this item, component or unit and made no representations of whether or not it was functioning as intended and will state a reason

for not inspecting.

Not Present (NP) = This item, component or unit is not in this home or building.

Repair or Replace (RR) = The item, component or unit is not functioning as intended, or needs further inspection by a qualified contractor. Items, components or

units that can be repaired to satisfactory condition may not need replacement.

1. Roofing

The inspector shall inspect from ground level or eaves: The roof covering. The gutters. The downspouts. The vents, flashings, skylights, chimney and other roof penetrations. The general structure of the roof from the readily accessible panels, doors or stairs.

The inspector is not required to: Walk on any roof surface, predict the service life expectancy, inspect underground downspout diverter drainage pipes, remove snow, ice, debris or other conditions that prohibit the observation of the roof surfaces, move insulation, inspect antennae, satellite dishes, lightning arresters, de-icing equipment, or similar attachments. Walk on any roof areas that appear, in the opinion of the inspector to be unsafe, and or cause damage. Perform a water test, warrant or certify the roof. Confirm proper fastening or installation of any roof material.

|

Roof Covering:

3-Tab fiberglass |

Viewed roof covering from:

Walked roof Camera Pole |

| IN | NI | NP | RR | ||

| 1.0 | Roof Coverings | • | • | ||

| 1.1 | Flashings | • | |||

| 1.2 | Skylights, Chimneys and Roof Penetrations | • | |||

| 1.3 | Roof Drainage Systems | • | |||

| IN | NI | NP | RR |

Comments:

2. Exterior

The inspector shall inspect: The siding, flashing and trim. All exterior doors, decks, stoops, steps, stairs, porches, railings, eaves, soffits and fascias. And report as in need of repair any spacing between intermediate balusters, spindles, or rails for steps, stairways, balconies, and railings that permit the passage of an object greater than four inches in diameter. A representative number of windows. The vegetation, surface drainage and retaining walls when these are likely to adversely affect the structure. And describe the exterior wall covering.

The inspector is not required to: Inspect or operate screens, storm windows, shutters, awnings, fences, outbuildings, or exterior accent lighting, Inspect items, including window and door flashings, which are not visible or readily accessible from the ground, Inspect geological, geotechnical, hydrological and/or soil conditions, Inspect recreational facilities, playground equipment. Inspect seawalls, break-walls and docks, Inspect erosion control and earth stabilization measures, Inspect for safety type glass, Inspect underground utilities, Inspect underground items, Inspect wells or springs, Inspect solar, wind or geothermal systems, Inspect swimming pools or spas, Inspect wastewater treatment systems septic systems or cesspools, Inspect irrigation or sprinkler systems, Inspect drain fields or drywells, Determine the integrity of multi-pane window glazing or the thermal window seals.

|

Siding Style:

Block and mortar |

Siding Material:

Masonry |

Exterior Entry Doors:

Steel |

|

Appurtenance:

Porch |

Driveway:

Concrete |

| IN | NI | NP | RR | ||

| 2.0 | Wall Cladding Flashing and Trim | • | |||

| 2.1 | Doors (Exterior) | • | |||

| 2.2 | Windows | • | |||

| 2.3 | Eaves, Soffits and Fascias | • | |||

| IN | NI | NP | RR |

3. Structural Components

The inspector shall inspect: The basement. The foundation. The crawlspace. The visible structural components. Any present conditions or clear indications of active water penetration observed by the inspector. And report any general indications of foundation movement that are observed by the inspector, such as but not limited to sheetrock cracks, brick cracks, out-of-square door frames or floor slopes.

The inspector is not required to: Enter any crawlspaces that are not readily accessible or where entry could cause damage or pose a hazard to the inspector, Move stored items or debris, Operate sump pumps with inaccessible floats, Identify size, spacing, span, location or determine adequacy of foundation bolting, bracing, joists, joist spans or support systems, Provide any engineering or architectural service, Report on the adequacy of any structural system or component.

|

Foundation:

Poured concrete |

Floor Structure:

Slab |

Wall Structure:

2 X 4 Wood |

|

Ceiling Structure:

2X4 |

Roof Structure:

2 X 4 Rafters |

Roof-Type:

Gable |

|

Method used to observe attic:

Walked |

Attic info:

Attic access Pull Down stairs Light in attic |

| IN | NI | NP | RR | ||

| 3.0 | Foundations, Basement and Crawlspace (Report signs of abnormal or harmful water penetration into the building or signs of abnormal or harmful condensation on building components.) | • | |||

| 3.1 | Walls (Structural) | • | |||

| 3.2 | Ceilings (Structural) | • | |||

| 3.3 | Roof Structure and Attic | • | |||

| IN | NI | NP | RR |

4. Heating / Central Air Conditioning

The inspector shall inspect: The heating system and describe the energy source and heating method using normal operating controls. And report as in need of repair electric furnaces which do not operate. And report if inspector deemed the furnace inaccessible. The central cooling equipment using normal operating controls. The fireplace, and open and close the damper door if readily accessible and operable. Hearth extensions and other permanently installed components. And report as in need of repair deficiencies in the lintel, hearth and material surrounding the fireplace, including clearance from combustible materials.

The inspector is not required to: Inspect or evaluate interiors of flues or chimneys, fire chambers, heat exchangers, humidifiers, dehumidifiers, electronic air filters, solar heating systems, solar heating systems or fuel tanks. Inspect underground fuel tanks. Determine the uniformity, temperature, flow, balance, distribution, size, capacity, BTU, or supply adequacy of the heating system. Light or ignite pilot flames. Activate heating, heat pump systems, or other heating systems when ambient temperatures or when other circumstances are not conducive to safe operation or may damage the equipment. Override electronic thermostats. Evaluate fuel quality. Verify thermostat calibration, heat anticipation or automatic setbacks, timers, programs or clocks. Determine the uniformity, temperature, flow, balance, distribution, size, capacity, BTU, or supply adequacy of the cooling system. Inspect window units, through-wall units, or electronic air filters. Operate equipment or systems if exterior temperature is below 60 degrees Fahrenheit or when other circumstances are not conducive to safe operation or may damage the equipment. Inspect or determine thermostat calibration, heat anticipation or automatic setbacks or clocks. Examine electrical current, coolant fluids or gasses, or coolant leakage. Inspect the flue or vent system. Inspect the interior of chimneys or flues, fire doors or screens, seals or gaskets, or mantels. Determine the need for a chimney sweep. Operate gas fireplace inserts. Light pilot flames. Determine the appropriateness of such installation. Inspect automatic fuel feed devices. Inspect combustion and/or make-up air devices. Inspect heat distribution assists whether gravity controlled or fan assisted. Ignite or extinguish fires. Determine draft characteristics. Move fireplace inserts, stoves, or firebox contents. Determine adequacy of draft, perform a smoke test or dismantle or remove any component. Perform an NFPA inspection. Perform a Phase 1 fireplace and chimney inspection.

|

Heat Type:

Electric heat |

Energy Source:

Electric |

Number of Heat Systems (excluding wood):

One |

|

Heat System Brand:

AIRTEMP |

Ductwork:

Insulated |

Filter Type:

Disposable |

|

Filter Size:

16×20 |

Cooling Equipment Type:

Air conditioner unit |

Cooling Equipment Energy Source:

Electricity |

|

Number of AC Only Units:

One |

Central Air Brand:

AIRTEMP |

Condenser Unit Model Number:

Model number Extra Info : VSA1BF4M1SN48K |

|

Condenser Unit Serial Number:

Serial Number Extra Info : VSG180220044 |

Air Handler Model Number:

Model Number Extra Info : B6EMMX48K-C |

Air Handler Serial Number:

Serial Number Extra Info : B6G180246851 |

| IN | NI | NP | RR | ||

| 4.0 | Heating Equipment | • | |||

| 4.1 | Normal Operating Controls | • | |||

| 4.2 | Automatic Safety Controls | • | |||

| 4.3 | Distribution Systems (including fans, pumps, ducts and piping, with supports, insulation, air filters, registers, radiators, fan coil units and convectors) | • | |||

| 4.4 | Presence of Installed Heat Source in Each Room | • | |||

| 4.5 | Cooling and Air Handler Equipment | • | |||

| 4.6 | Normal Operating Controls | • | |||

| 4.7 | Presence of Installed Cooling Source in Each Room | • | |||

| IN | NI | NP | RR |

Comments:

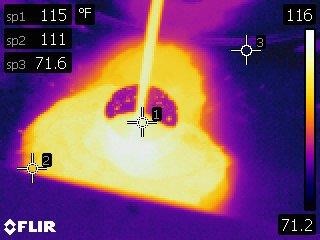

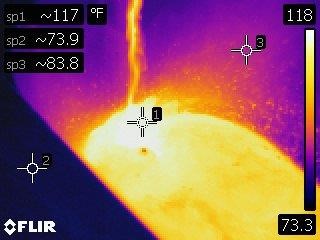

At the time of inspection there was a 15 degree temperature split in the cooling cycle. This is well withing the normal range.

5. Plumbing System

The inspector shall: Verify the presence of and identify the location of the main water shutoff valve. Inspect the water heating equipment, including combustion air, venting, connections, energy sources, seismic bracing, and verify the presence or absence of temperature-pressure relief valves and/or Watts 210 valves. Flush toilets. Run water in sinks, tubs, and showers. Inspect the interior water supply including all fixtures and faucets. Inspect the drain, waste and vent systems, including all fixtures. Describe any visible fuel storage systems. Inspect the drainage sump pumps testing sumps with accessible floats. Inspect and describe the water supply, drain, waste and main fuel shut-off valves, as well as the location of the water main and main fuel shut-off valves. Inspect and determine if the water supply is public or private. Inspect and report as in need of repair deficiencies in the water supply by viewing the functional flow in two fixtures operated simultaneously. Inspect and report as in need of repair deficiencies in installation and identification of hot and cold faucets. Inspect and report as in need of repair mechanical drain-stops that are missing or do not operate if installed in sinks, lavatories and tubs. Inspect and report as in need of repair commodes that have cracks in the ceramic material, are improperly mounted on the floor, leak, or have tank components which do not operate.

The inspector is not required to: Light or ignite pilot flames. Determine the size, temperature, age, life expectancy or adequacy of the water heater. Inspect interiors of flues or chimneys, water softening or filtering systems, well pumps or tanks, safety or shut-of valves, floor drains, lawn sprinkler systems or fire sprinkler systems. Determine the exact flow rate, volume, pressure, temperature, or adequacy of the water supply. Determine the water quality or potability or the reliability of the water supply or source. Open sealed plumbing access panels. Inspect clothes washing machines or their connections. Operate any main, branch or fixture valve. Test shower pans, tub and shower surrounds or enclosures for leakage. Evaluate the compliance with local or state conservation or energy standards, or the proper design or sizing of any water, waste or venting components, fixtures or piping. Determine the effectiveness of anti-siphon, back-flow prevention or drain-stop devices. Determine whether there are sufficient clean-outs for effective cleaning of drains. Evaluate gas, liquid propane or oil storage tanks. Inspect any private sewage waste disposal system or component of. Inspect water treatment systems or water filters. Inspect water storage tanks, pressure pumps or bladder tanks. Evaluate time to obtain hot water at fixtures, or perform testing of any kind to water heater elements. Evaluate or determine the adequacy of combustion air. Test, operate, open or close safety controls, manual stop valves and/or temperature or pressure relief valves. Examine ancillary systems or components, such as, but not limited to, those relating to solar water heating, hot water circulation.

|

Water Source:

Well |

Plumbing Water Supply (into home):

CPVC PVC |

Plumbing Water Distribution (inside home):

CPVC |

|

Washer Drain Size:

2″ Diameter |

Plumbing Waste:

PVC |

Water Heater Power Source:

Electric |

|

Water Heater Capacity:

40 Gallon (1-2 people) |

Water Heater Location:

Closet downstairs |

WH Manufacturer:

RHEEM |

|

Water Heater Model Number:

Model Number Extra Info : XE40T06ST45U1 |

Water Heater Serial Number:

Serial Number Extra Info : A451812369 |

| IN | NI | NP | RR | ||

| 5.0 | Plumbing Drain, Waste and Vent Systems | • | |||

| 5.1 | Plumbing Water Supply, Distribution System and Fixtures | • | • | ||

| 5.2 | Hot Water Systems, Controls, Chimneys, Flues and Vents | • | |||

| 5.3 | Main Water Shut-off Device (Describe location) | • | |||

| IN | NI | NP | RR |

Comments:

The water pressure at the time of inspection was recorded at 36 PSI.

The sink faucets is loose at the hall bath. Repairs are needed. A qualified licensed plumber should repair or correct as needed.

The sink faucets hot control and cold control is reversed (hot is cold, cold is hot) at the hall bath. Repairs are needed. A qualified licensed plumber should repair or correct

as needed.

The water temperature was recorded at 115-120 degrees at each plumbing fixture. This water heater temperature setting is well within the normal, safe range.

The main water shut off valve is located in the utility room.

6. Electrical System

The inspector shall inspect: The service line. The meter box. The main disconnect. And determine the rating of the service amperage. Panels, breakers and fuses. The service grounding and bonding. A representative sampling of switches, receptacles, light fixtures, AFCI receptacles and test all GFCI receptacles and GFCI circuit breakers observed and deemed to be GFCI’s during the inspection. And report the presence of solid conductor aluminum branch circuit wiring if readily visible. And report on any GFCI-tested receptacles in which power is not present, polarity is incorrect, the receptacle is not grounded, is not secured to the wall, the cover is not in place, the ground fault circuit interrupter devices are not properly installed or do not operate properly, or evidence of arcing or excessive heat is present. The service entrance conductors and the condition of their sheathing. The ground fault circuit interrupters observed and deemed to be GFCI’s during the inspection with a GFCI tester. And describe the amperage rating of the service. And report the absence of smoke detectors. Service entrance cables and report as in need of repair deficiencies in the integrity of the insulation, drip loop, or separation of conductors at weatherheads and clearances.

The inspector is not required to: Insert any tool, probe or device into the main panel, sub-panels, downstream panel, or electrical fixtures. Operate electrical systems that are shut down. Remove panel covers or dead front covers if not readily accessible. Operate over current protection devices. Operate non-accessible smoke detectors. Measure or determine the amperage or voltage of the main service if not visibly labeled. Inspect the alarm system and components. Inspect the ancillary wiring or remote control devices. Activate any electrical systems or branch circuits which are not energized. Operate overload devices. Inspect low voltage systems, electrical de-icing tapes, swimming pool wiring or any time-controlled devices. Verify the continuity of the connected service ground. Inspect private or emergency electrical supply sources, including but not limited to generators, windmills, photovoltaic solar collectors, or battery or electrical storage facility. Inspect spark or lightning arrestors. Conduct voltage drop calculations. Determine the accuracy of breaker labeling. Inspect exterior lighting.

|

Electrical Service Conductors:

Overhead service |

Panel Capacity:

200 AMP |

Panel Type:

Circuit breakers |

|

Electric Panel Manufacturer:

SQUARE D |

Branch wire 15 and 20 AMP:

Copper |

Wiring Methods:

Romex |

| IN | NI | NP | RR | ||

| 6.0 | Service Entrance Conductors | • | • | ||

| 6.1 | Service and Grounding Equipment, Main Overcurrent Device, Main and Distribution Panels | • | • | ||

| 6.2 | Branch Circuit Conductors, Overcurrent Devices and Compatability of their Amperage and Voltage | • | |||

| 6.3 | Connected Devices and Fixtures (Observed from a representative number operation of ceiling fans, lighting fixtures, switches and receptacles located inside the house, garage, and on the dwelling’s exterior walls) | • | • | ||

| 6.4 | Polarity and Grounding of Receptacles within 6 feet of interior plumbing fixtures, all receptacles in garage, carport and exterior walls of inspected structure | • | |||

| 6.5 | Operation of GFCI (Ground Fault Circuit Interrupters) | • | • | ||

| 6.6 | Location of Main and Distribution Panels | • | |||

| 6.7 | Smoke Detectors | • | |||

| IN | NI | NP | RR |

Comments:

The Service Entrance Conductors service conductor mast is loose or leaning above the roof line. I recommend a licensed electrical contractor inspect further and correct

as needed.

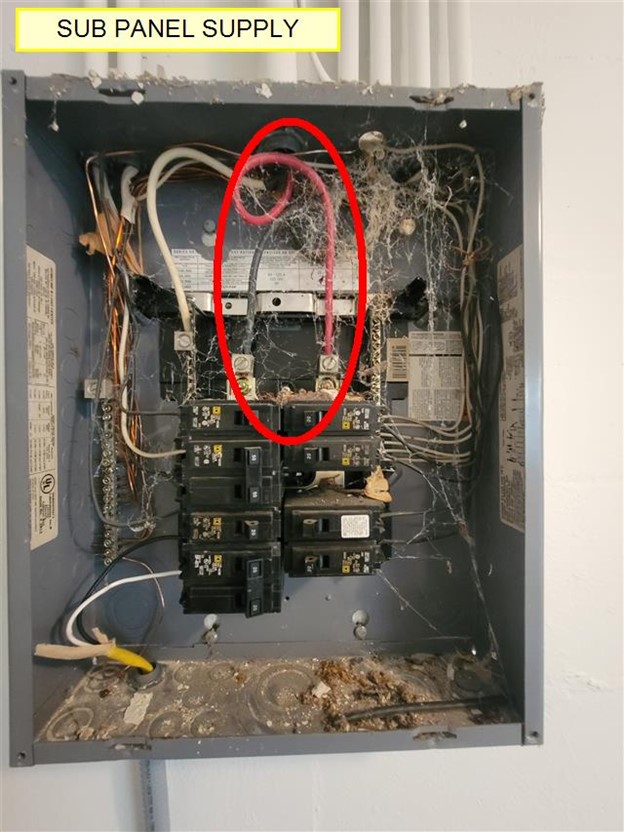

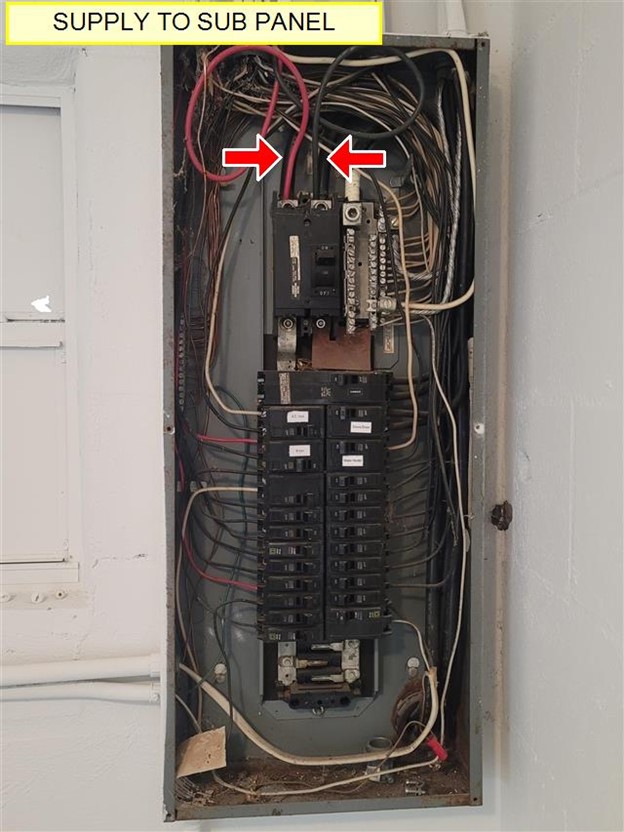

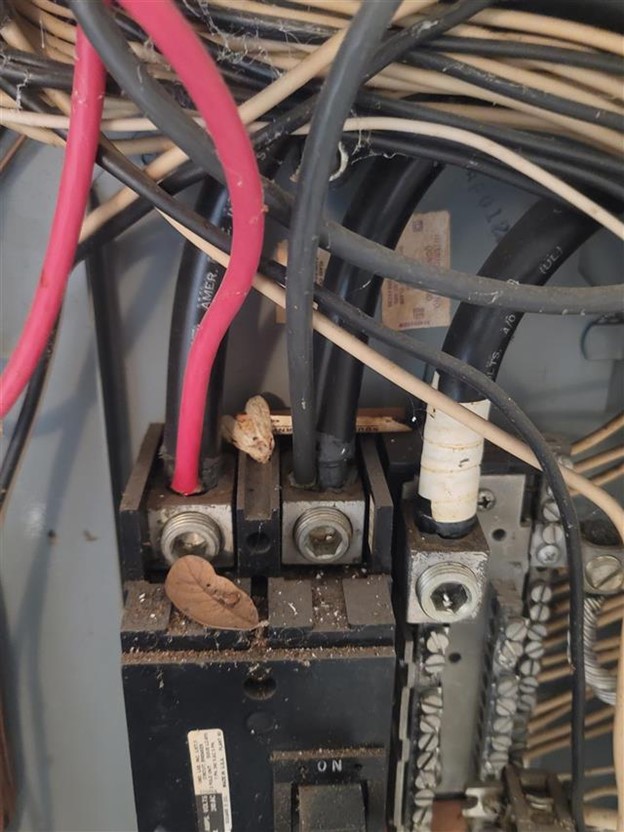

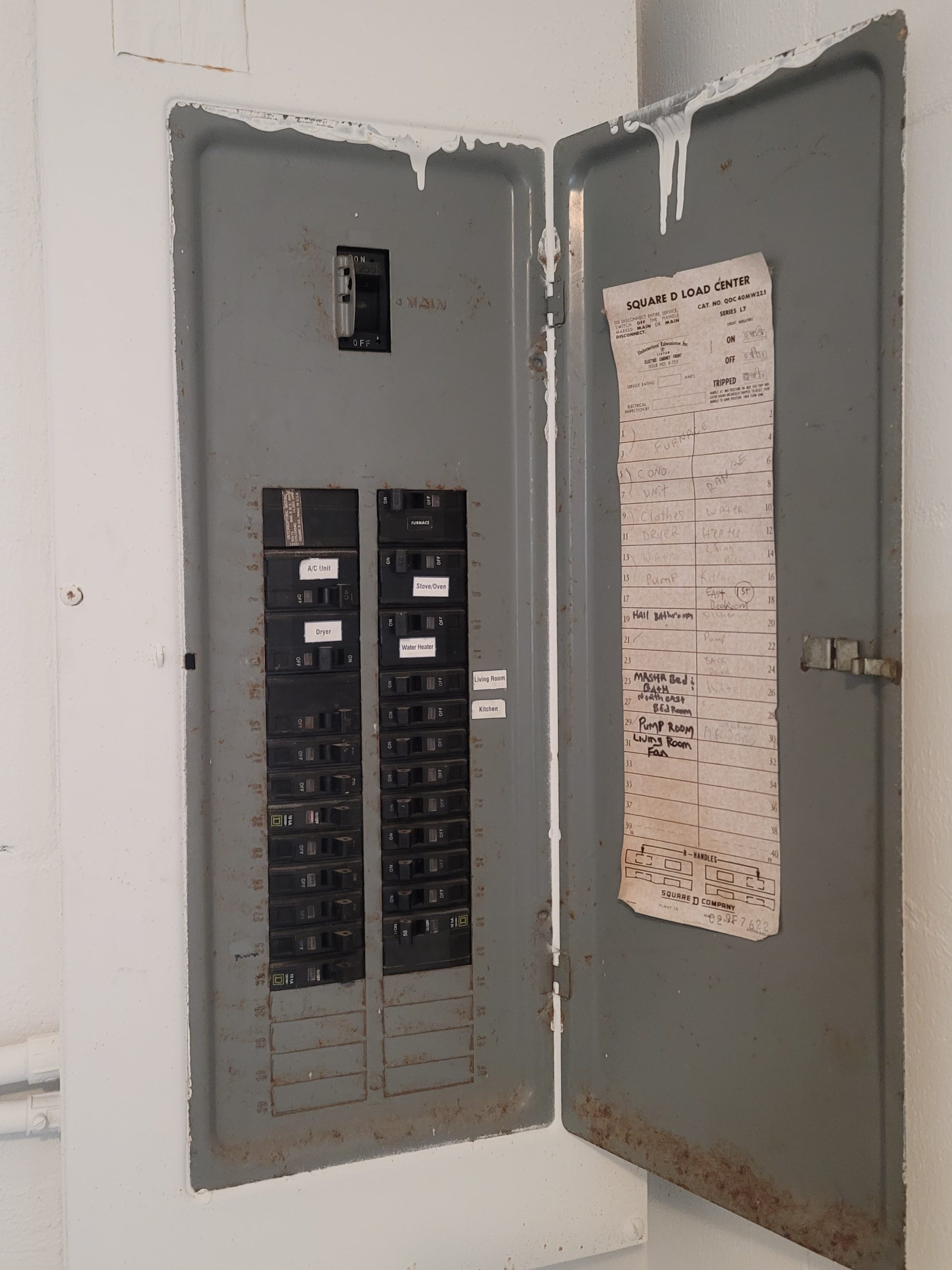

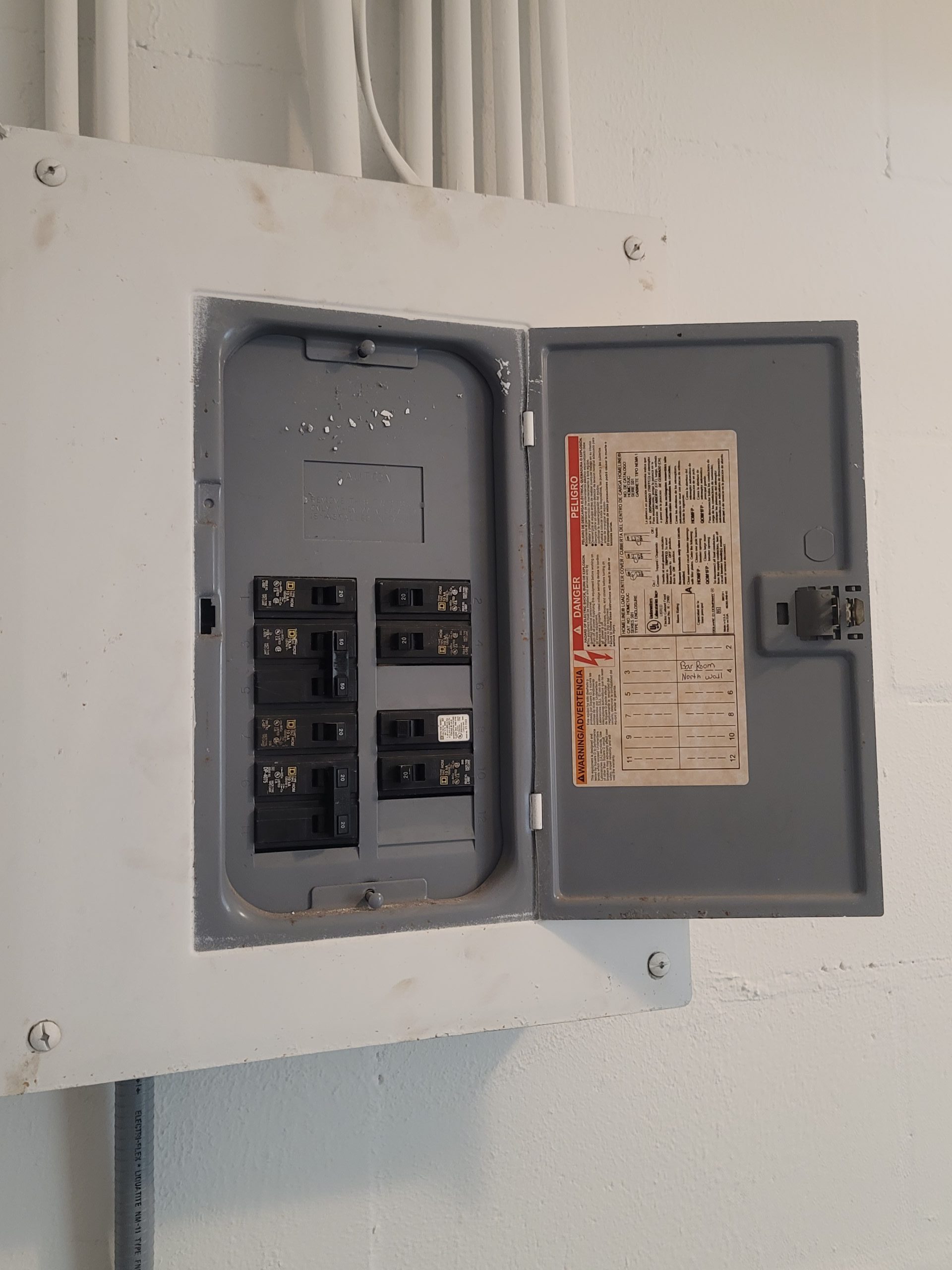

The main breaker is missing for the sub panel. The power for the sub panel is coming directly from the SEC on the supply side of the breaker in the main panel. The sub

panel needs a breaker installed in the main panel and the supply wires going to the sub panel should feed from that breaker.

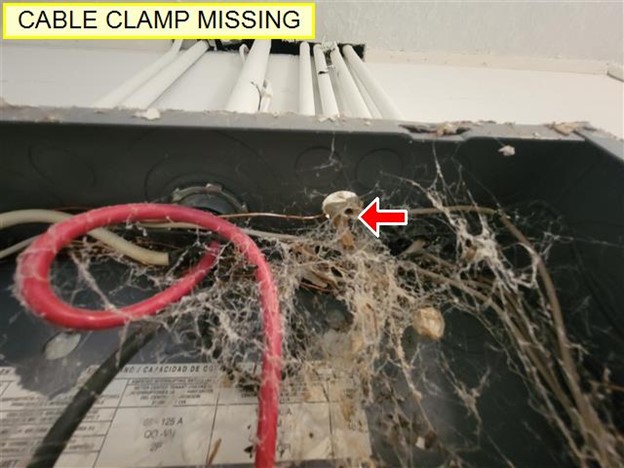

The main panel box is located at the storage room. The main and sub panel is missing a knockout plug and cable clamps. Electrical issues are considered a hazard until

repaired. I recommend repair as needed.

There are several missing electrical cover-plates in the garage and in the home. Electrical issues are considered a hazard until repaired. I recommend repair as needed.

The light fixture does not work at the South side of home. The electrical whip is not connected. I recommend repair as needed.

Two outlets are producing partial or no voltage in the bedrooms on the East side of the home. I recommend repair as needed.

The light fixture is missing at the Guest Bedroom closet. Electrical issues are considered a hazard until repaired. I recommend repair as needed.

GFCI (Ground Fault Circuit Interrupter) outlets at the Kitchen, Master bath and Hall Bath wont “trip” when tested. All outlets located in wet areas, including kitchens and

bathrooms, should be GFCI protected. Electrical issues are considered a hazard until repaired. I recommend repair as needed.

The main panel box is located at the utility room.

7. Insulation and Ventilation

|

Attic Insulation:

Cellulose |

Ventilation:

Gable vents |

Dryer Power Source:

220 Electric |

| IN | NI | NP | RR | ||

| 7.0 | Insulation in Attic | • | • | ||

| 7.1 | Ventilation of Attic and Foundation Areas | • | |||

| 7.2 | Venting Systems (Kitchens, Baths and Laundry) | • | |||

| IN | NI | NP | RR |

Comments:

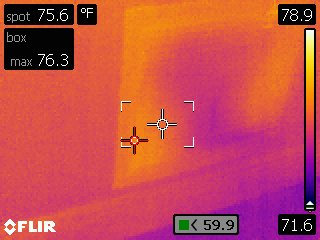

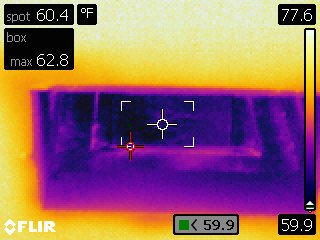

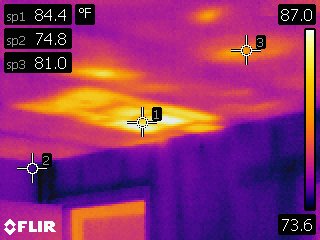

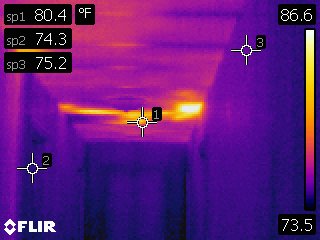

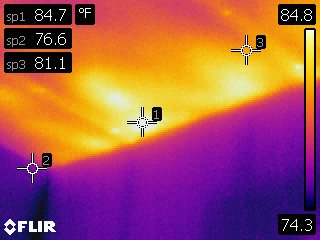

Insulation in attic is missing or not effectively insulating in three small areas in the home. Locations include above the entry door, hall way, and North East bedroom. Heat

loss can occur more on this home than one that is properly insulated. A qualified person should repair or replace as needed.

8. Interiors

The home inspector shall observe: Walls, ceiling, and floors; Steps, stairways, balconies, and railings; Counters and a representative number of installed cabinets; and A representative number of doors and windows. The home inspector shall: Operate a representative number of windows and interior doors; and Report signs of abnormal or harmful water penetration into the building or signs of abnormal or harmful condensation on building components. The home inspector is not required to observe: Paint, wallpaper, and other finish treatments on the interior walls, ceilings, and floors; Carpeting; or Draperies, blinds, or other window treatments.

The inspector shall: Open and close a representative number of doors and windows. Inspect the walls, ceilings, steps, stairways, and railings. Inspect garage doors and garage door openers by operating first by remote (if available) and then by the installed automatic door control. And report as in need of repair any installed electronic sensors that are not operable or not installed at proper heights above the garage door. And report as in need of repair any door locks or side ropes that have not been removed or disabled when garage door opener is in use. And report as in need of repair any windows that are obviously fogged or display other evidence of broken seals.

The inspector is not required to: Inspect paint, wallpaper, window treatments or finish treatments. Inspect central vacuum systems. Inspect safety glazing. Inspect security systems or components. Evaluate the fastening of countertops, cabinets, sink tops and fixtures, or firewall compromises. Move furniture, stored items, or any coverings like carpets or rugs in order to inspect the concealed floor structure. Move drop ceiling tiles. Inspect or move any household appliances. Inspect or operate equipment housed in the garage except as otherwise noted. Verify or certify safe operation of any auto reverse or related safety function of a garage door. Operate or evaluate security bar release and opening mechanisms, whether interior or exterior, including compliance with local, state, or federal standards. Operate any system, appliance or component that requires the use of special keys, codes, combinations, or devices. Operate or evaluate self-cleaning oven cycles, tilt guards/latches or signal lights. Inspect microwave ovens or test leakage from microwave ovens. Operate or examine any sauna, steam-jenny, kiln, toaster, ice-maker, coffee-maker, can-opener, bread-warmer, blender, instant hot water dispenser, or other small, ancillary devices. Inspect elevators. Inspect remote controls. Inspect appliances. Inspect items not permanently installed. Examine or operate any above-ground, movable, freestanding, or otherwise non-permanently installed pool/spa, recreational equipment or self-contained equipment. Come into contact with any pool or spa water in order to determine the system structure or components. Determine the adequacy of spa jet water force or bubble effect. Determine the structural integrity or leakage of a pool or spa.

|

Ceiling Materials:

Gypsum Board |

Wall Material:

Gypsum Board |

Floor Covering(s):

Carpet Tile |

|

Interior Doors:

Hollow core Raised panel Wood |

Window Types:

Thermal/Insulated Single pane |

Window Manufacturer:

UNKNOWN |

|

Cabinetry:

Wood |

Countertop:

Granite |

| IN | NI | NP | RR | ||

| 8.0 | Ceilings | • | |||

| 8.1 | Walls | • | • | ||

| 8.2 | Floors | • | |||

| 8.3 | Counters and Cabinets (representative number) | • | |||

| 8.4 | Doors (representative number) | • | • | ||

| 8.5 | Windows (representative number) | • | |||

| IN | NI | NP | RR |

Comments:

The block wall is damaged at the garage and Utility room. This damage is considered cosmetic. A qualified person should repair or replace as needed.

The striker plate is missing at laundry room door. I recommend repair or replace by a qualified person.

9. Garage

|

Garage Door Type:

Two automatic |

Garage Door Material:

Metal |

Auto-opener Manufacturer:

GENIE Extra Info : SERIAL# 190184110299IQ |

| IN | NI | NP | RR | ||

| 9.0 | Garage Floor | • | |||

| 9.1 | Garage Door (s) | • | |||

| 9.2 | Garage Door Operators (Report whether or not doors will reverse when met with resistance) | • | |||

| IN | NI | NP | RR |

Comments:

The garage door will reverse when met with resistance.

The sensors are in place for garage door(s) and will reverse the door.

10. Built-In Kitchen Appliances

|

Dishwasher Brand:

FRIGIDAIRE Serial # : TH04178530 |

Range/Oven:

FRIGIDAIRE Serial # : VF04616016 |

Built in Microwave:

FRIGIDAIRE Serial # : KG03100057 |

|

Refrigerator:

FRIGIDAIRE Serial # : 4A04706658 |

| IN | NI | NP | RR | ||

| 10.0 | Dishwasher | • | |||

| 10.1 | Ranges/Ovens/Cooktops | • | |||

| 10.2 | Range Hood (s) | • | |||

| 10.3 | Microwave Cooking Equipment | • | |||

| 10.4 | Refrigerator | • | |||

| IN | NI | NP | RR |

11. Water Wells

|

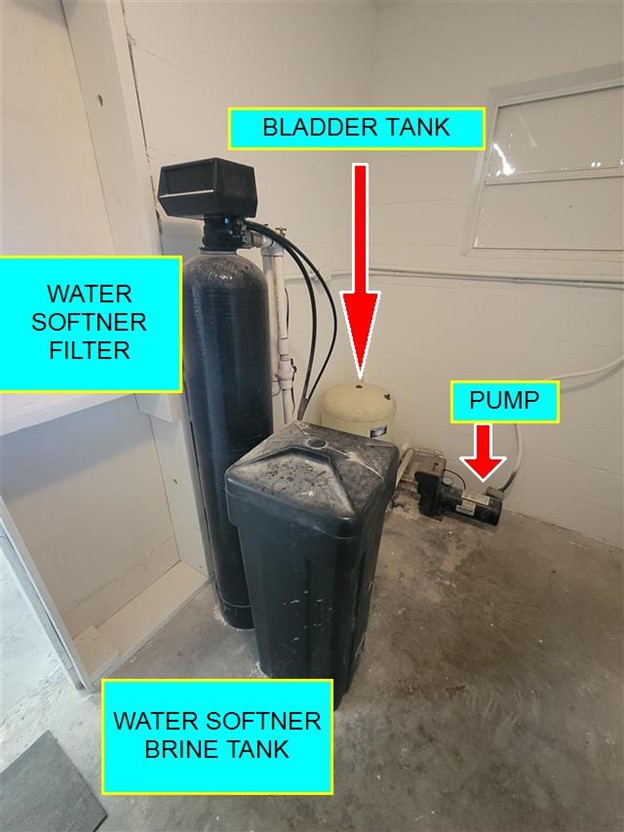

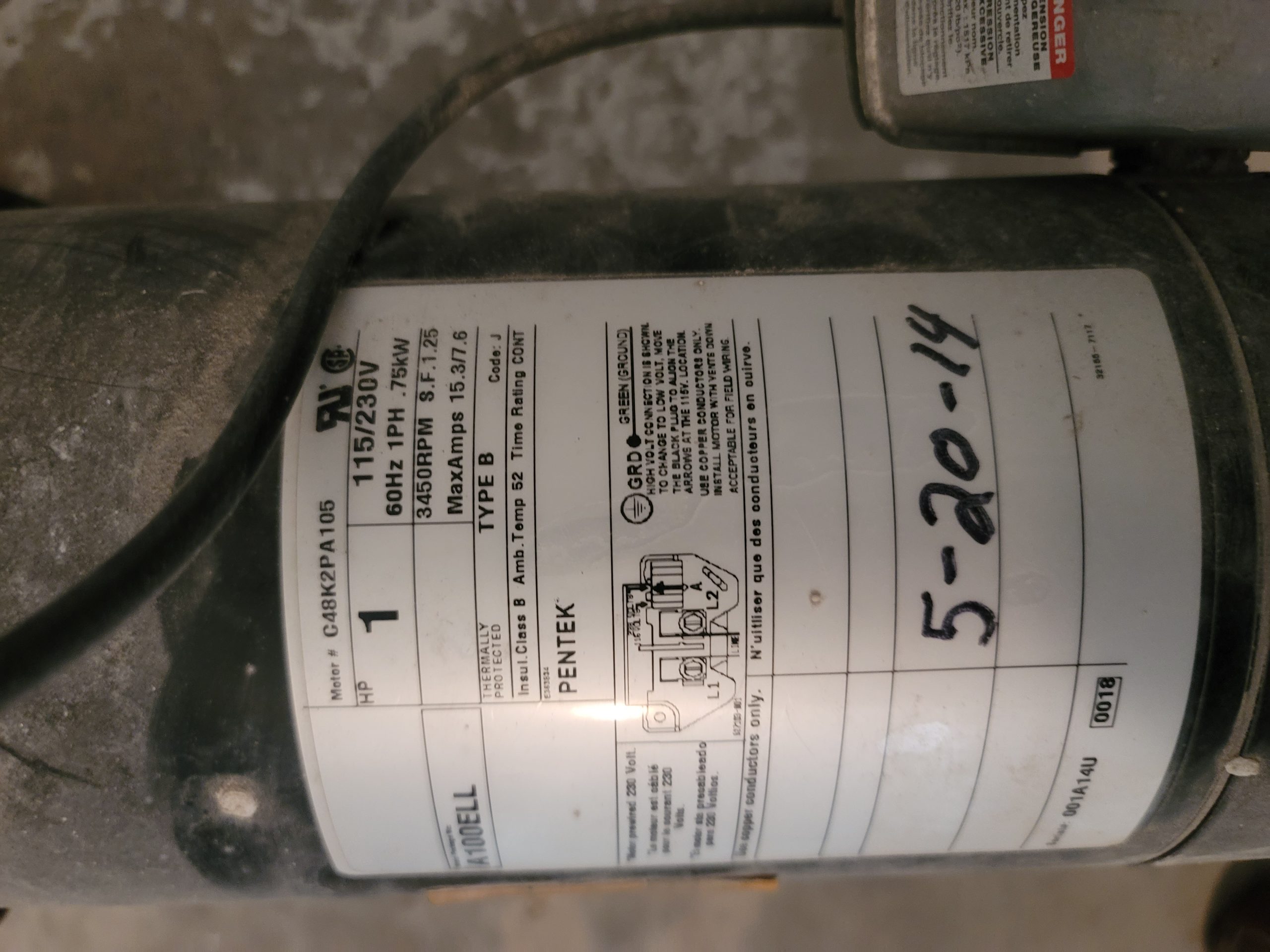

Pump Type:

Above ground |

Accessories:

Air bladder tank |

Pump Model Number:

Model Number Extra Info : A100ELL |

| IN | NI | NP | RR | ||

| 11.0 | Well Pump and Equipment | • | |||

| IN | NI | NP | RR |

Comments:

The well pump and water softener equipment is located in the utility room and protected from the elements. The equipment was found to be in working order at the time of

inspection.

Summary

Saint Cloud Florida 34771

321-877-6247

Customer

John Austin

Address

6715 Bass Hwy

St Cloud FL 34771

| 1.0 | Roof Coverings | |

| Inspected, Repair or Replace | ||

|

The roof covering has excessive granule loss and is nearing the end of its life cycle. No leaks were found at the time of inspection.

1.0 Item 1 (Picture)

1.0 Item 2 (Picture)

1.0 Item 3 (Picture)

|

||

| 5.1 | Plumbing Water Supply, Distribution System and Fixtures | |

| Inspected, Repair or Replace | ||

|

(2) The sink faucets is loose at the hall bath. Repairs are needed. A qualified licensed plumber should repair or correct as needed. 5.1 Item 2 (Video)

|

||

|

(3) The sink faucets hot control and cold control is reversed (hot is cold, cold is hot) at the hall bath. Repairs are needed. A qualified licensed plumber should repair or correct

as needed.

5.1 Item 3 (Picture)

|

||

| 6.0 | Service Entrance Conductors | |

| Inspected, Repair or Replace | ||

|

The Service Entrance Conductors service conductor mast is loose or leaning above the roof line. I recommend a licensed electrical contractor inspect further and correct

as needed.

6.0 Item 1 (Picture)

6.0 Item 2 (Picture)

6.0 Item 3 (Picture)

|

||

| 6.1 | Service and Grounding Equipment, Main Overcurrent Device, Main and Distribution Panels | |

| Inspected, Repair or Replace | ||

|

(1) The main breaker is missing for the sub panel. The power for the sub panel is coming directly from the SEC on the supply side of the breaker in the main panel. The sub

panel needs a breaker installed in the main panel and the supply wires going to the sub panel should feed from that breaker.

6.1 Item 1 (Picture)

6.1 Item 2 (Picture)

6.1 Item 3 (Picture)

|

||

|

(2) The main panel box is located at the storage room. The main and sub panel is missing a knockout plug and cable clamps. Electrical issues are considered a hazard until

repaired. I recommend repair as needed.

6.1 Item 4 (Picture)

6.1 Item 5 (Picture)

6.1 Item 6 (Picture)

|

||

| 6.3 | Connected Devices and Fixtures (Observed from a representative number operation of ceiling fans, lighting fixtures, switches and receptacles located inside the house, garage, and on the dwelling’s exterior walls) | |

| Inspected, Repair or Replace | ||

|

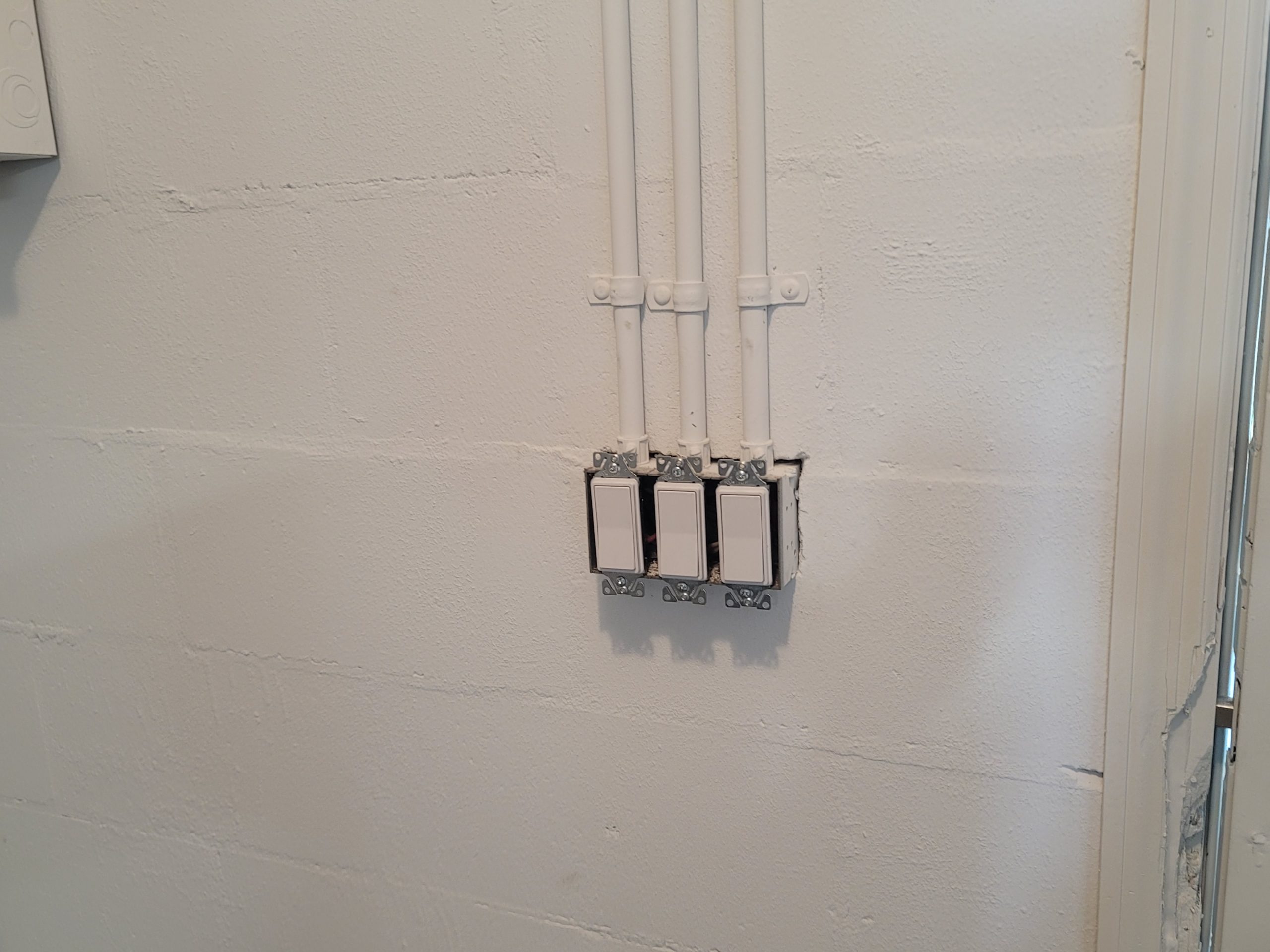

(1) There are several missing electrical cover-plates in the garage and in the home. Electrical issues are considered a hazard until repaired. I recommend repair as needed.

6.3 Item 1 (Picture)

6.3 Item 2 (Picture)

6.3 Item 3 (Picture)

6.3 Item 4 (Picture)

6.3 Item 5 (Picture)

6.3 Item 6 (Picture)

6.3 Item 7 (Picture)

|

||

|

(2) The light fixture does not work at the South side of home. The electrical whip is not connected. I recommend repair as needed.

6.3 Item 9 (Picture)

|

||

|

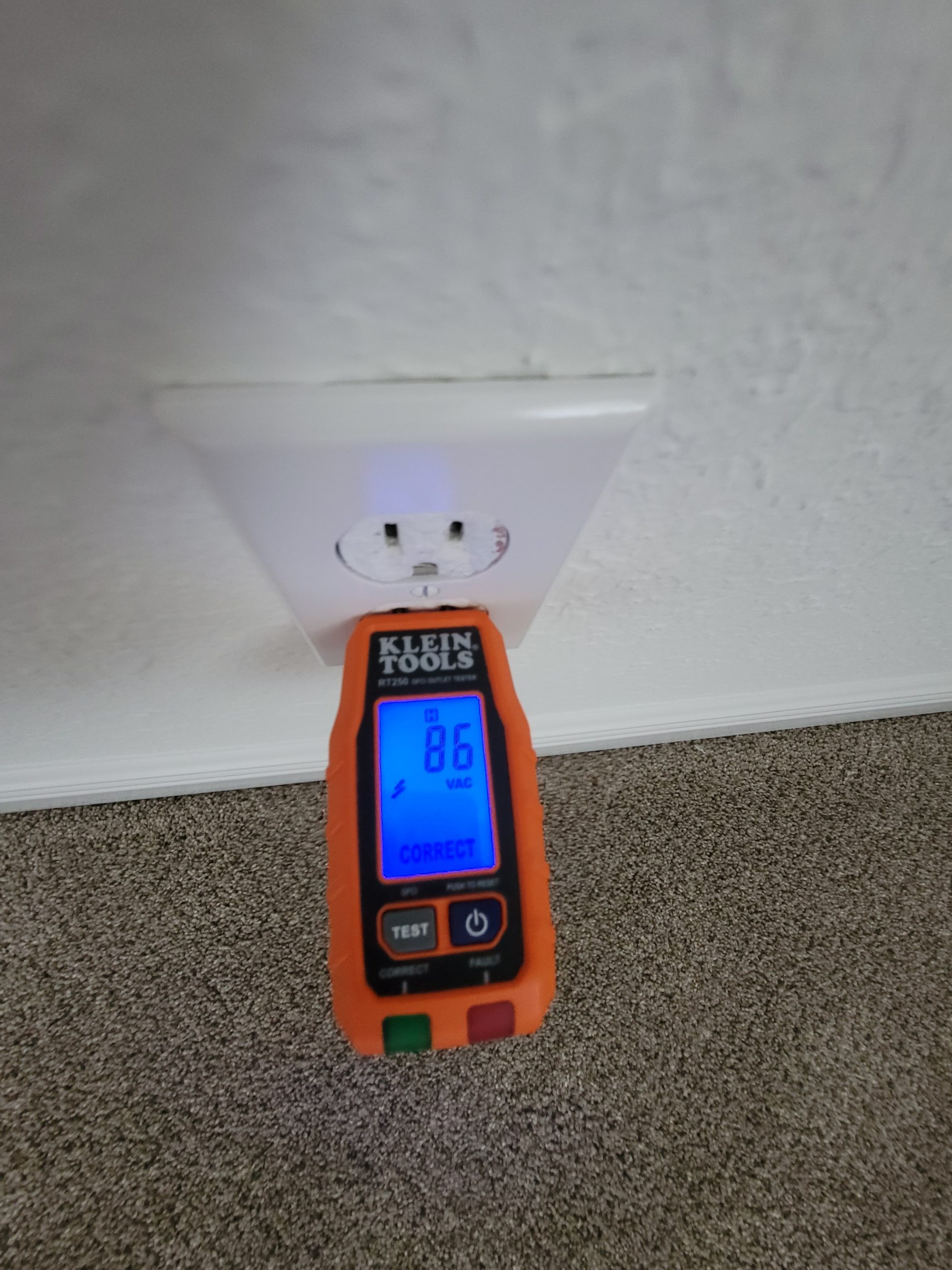

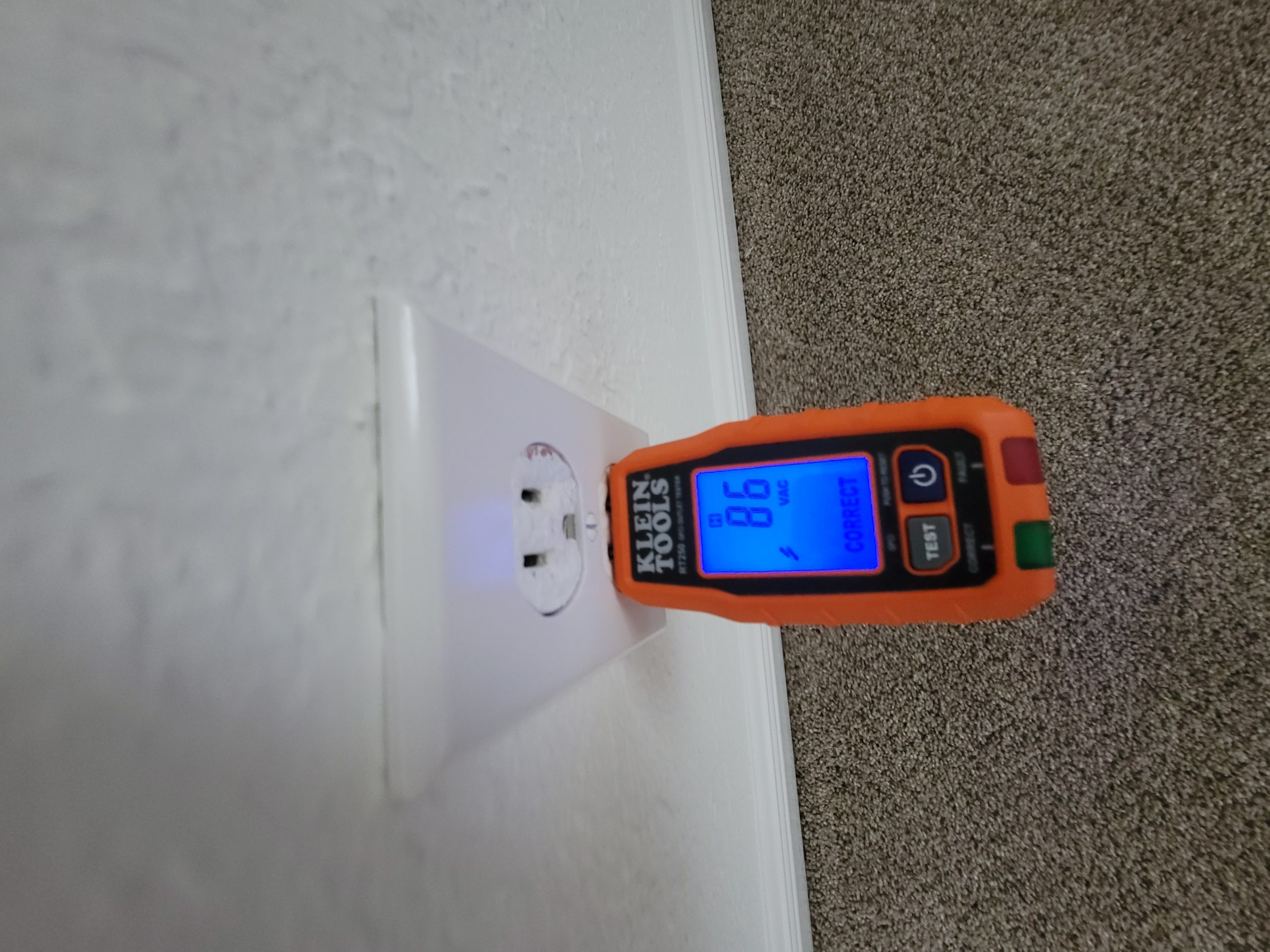

(3) Two outlets are producing partial or no voltage in the bedrooms on the East side of the home. I recommend repair as needed.

6.3 Item 10 (Picture)

6.3 Item 11 (Picture)

|

||

|

(4) The light fixture is missing at the Guest Bedroom closet. Electrical issues are considered a hazard until repaired. I recommend repair as needed.

6.3 Item 14 (Picture)

|

||

| 6.5 | Operation of GFCI (Ground Fault Circuit Interrupters) | |

| Inspected, Repair or Replace | ||

|

GFCI (Ground Fault Circuit Interrupter) outlets at the Kitchen, Master bath and Hall Bath wont “trip” when tested. All outlets located in wet areas, including kitchens and

bathrooms, should be GFCI protected. Electrical issues are considered a hazard until repaired. I recommend repair as needed.

6.5 Item 1 (Video)

6.5 Item 2 (Video)

6.5 Item 3 (Video)

|

||

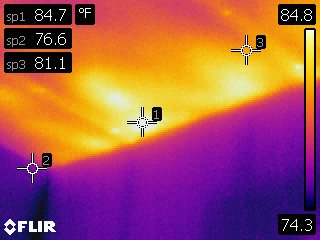

| 7.0 | Insulation in Attic | ||

| Inspected, Repair or Replace | |||

|

Insulation in attic is missing or not effectively insulating in three small areas in the home. Locations include above the entry door, hall way, and North East bedroom. Heat

loss can occur more on this home than one that is properly insulated. A qualified person should repair or replace as needed.

7.0 Item 1 (Picture)

7.0 Item 2 (Picture)

7.0 Item 3 (Picture)

7.0 Item 4 (Picture)

7.0 Item 5 (Picture)

7.0 Item 6 (Picture)

|

|||

| 8.1 | Walls | |

| Inspected, Repair or Replace | ||

|

The block wall is damaged at the garage and Utility room. This damage is considered cosmetic. A qualified person should repair or replace as needed.

8.1 Item 1 (Picture)

8.1 Item 2 (Picture)

|

||

| 8.4 | Doors (representative number) | |

| Inspected, Repair or Replace | ||

|

The striker plate is missing at laundry room door. I recommend repair or replace by a qualified person.

8.4 Item 1 (Picture)

|

||

Prepared Using HomeGauge http://www.HomeGauge.com : Licensed To Jay Peters

The roof covering has two shingle tabs missing at the ridge on the North side of the home. Repair by a qualified person is recommended.